Understanding the Manufacturing of Fiberglass Square Tubes

Fiberglass square tubes are becoming increasingly popular in industries ranging from construction to automotive due to their unique properties and versatility. These tubes are known for their high strength, lightweight design, and resistance to corrosion, making them ideal for applications where durability and longevity are essential. This blog will delve into the manufacturing process of fiberglass square tubes, exploring the materials used, the different techniques employed, and the benefits of utilizing them in various applications.

What is a Fiberglass Square Tube?

Fiberglass square tubes are hollow structural elements made from fiberglass, a composite material consisting of fine glass fibers embedded in a resin matrix. These tubes are shaped into square or rectangular profiles and are often used as structural components in applications that demand both strength and lightweight properties.

Fiberglass itself is a remarkable material that is stronger than steel but lighter than metal, making it ideal for use in applications where both weight and strength are important. Additionally, fiberglass is highly resistant to environmental elements such as moisture, heat, and chemicals, making it suitable for use in challenging environments where other materials might deteriorate.

Key Benefits of Fiberglass Square Tubes

Before diving into the manufacturing process, it’s essential to understand why fiberglass square tubes are becoming a popular choice in various industries. Here are some key benefits of using fiberglass square tubes:

- Corrosion Resistance: Unlike metal tubes, fiberglass square tubes do not corrode or rust, making them an excellent choice for use in moist or chemically aggressive environments. This property is especially beneficial in industries like marine construction, chemical plants, and outdoor applications.

- Lightweight: Fiberglass is significantly lighter than metals like steel or aluminum, which helps reduce the overall weight of structures without sacrificing strength. This is particularly advantageous in applications such as transportation and construction, where weight savings can result in cost reductions and better performance.

- Strength and Durability: Despite their lightweight nature, fiberglass square tubes are incredibly strong and durable. They can withstand significant loads and resist impact damage, making them ideal for structural applications that require both support and resilience.

- Thermal Insulation: Fiberglass also offers excellent thermal insulation properties, making it a great choice for applications that require heat resistance or temperature control. Whether in high-temperature environments or cold storage, fiberglass square tubes help maintain consistent temperatures.

- Non-Conductive Properties: As an electrical insulator, fiberglass square tubes are ideal for use in electrical applications where conductivity must be avoided, such as in electrical enclosures and components.

The Materials Used in Manufacturing Fiberglass Square Tubes

The primary materials used to manufacture fiberglass square tubes are the fiberglass itself and the resin matrix that binds the fibers together. The two main components of fiberglass are:

- Glass Fibers: These fibers are the key structural element of fiberglass, providing its strength. The fibers are usually made from silica, boron, or other glass-forming materials that are drawn into fine strands. These fibers are woven or layered to form the structural framework of the tube.

- Resin: Resin is the binding material that holds the glass fibers together. Epoxy, polyester, and vinyl ester are commonly used resins in the production of fiberglass square tubes. The resin matrix provides the necessary rigidity and resistance to environmental factors like moisture, chemicals, and UV radiation.

The combination of these materials creates a composite structure that offers high strength-to-weight ratios, resistance to environmental degradation, and overall durability.

The Manufacturing Process of Fiberglass Square Tubes

The process of manufacturing fiberglass square tubes involves several key stages, including material preparation, pultrusion, and curing. Let’s walk through each step of the process:

1. Material Preparation

The first step in manufacturing fiberglass square tubes is preparing the raw materials. This involves cutting the glass fibers to the appropriate length and preparing the resin mixture. The resin is typically mixed with a hardening agent that allows it to cure and solidify once it is applied to the fiberglass fibers.

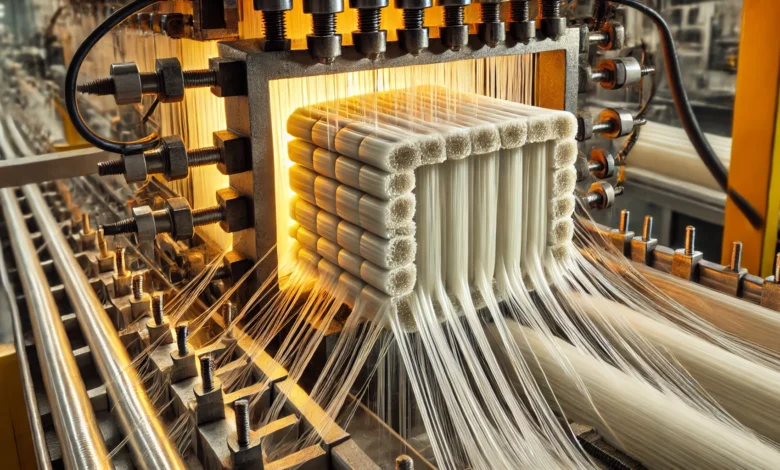

2. Pultrusion Process

The most common method for manufacturing fiberglass square tubes is called pultrusion. This continuous manufacturing process involves pulling the prepared fiberglass fibers through a resin bath, where they are thoroughly coated with the resin mixture.

Once the fibers are fully saturated with resin, they are pulled through a heated die that shapes them into the desired square tube profile. The heat causes the resin to cure and harden, creating a solid, rigid structure. This process can be done continuously, allowing for the production of fiberglass square tubes in long lengths.

3. Curing and Cooling

After the fiberglass square tubes are pulled through the heated die, they are subjected to a curing process. Curing typically takes place in a long oven or cooling chamber, where the resin fully hardens. This ensures that the tubes achieve their maximum strength and durability. Once the curing process is complete, the tubes are allowed to cool, which solidifies their structure.

4. Cutting and Finishing

Once the fiberglass square tubes have cooled, they are cut to the desired length using a cutting machine. The tubes are then inspected for quality, with any imperfections removed. Depending on the intended use, the tubes may undergo additional finishing steps, such as sanding, coating, or painting, to enhance their appearance or protect them from further environmental factors.

Applications of Fiberglass Square Tubes

Fiberglass square tubes are used in a wide range of industries due to their unique combination of properties. Some common applications include:

- Construction: In construction, fiberglass square tubes are often used for structural reinforcement in bridges, buildings, and other infrastructure projects. Their corrosion resistance makes them ideal for outdoor and marine applications, where traditional steel and metal materials would degrade over time.

- Transportation: The automotive and aerospace industries use fiberglass square tubes for lightweight structural components. This helps reduce the weight of vehicles and aircraft, improving fuel efficiency and performance.

- Electrical and Telecommunication: Fiberglass square tubes are also used in electrical enclosures and telecommunication towers. Their non-conductive properties ensure safe and reliable performance in electrical applications.

- Marine: The marine industry benefits from fiberglass square tubes due to their resistance to water and salt. These tubes are used in boat construction, docks, and marine structures where exposure to the elements is a concern.

- Sports and Recreation: Fiberglass square tubes are commonly used in the manufacturing of sports equipment like poles, racks, and stands, where strength and lightweight construction are essential.

Conclusion

Fiberglass square tubes are an indispensable component in many industries, offering strength, durability, and versatility. Their lightweight nature combined with their resistance to corrosion and harsh environments makes them an ideal choice for a wide range of applications, from construction to transportation and beyond.

Understanding the manufacturing process behind fiberglass square tubes helps explain why they have become such a valuable material in modern industry. By utilizing pultrusion technology and carefully selecting materials, manufacturers can produce high-quality fiberglass square tubes that meet the demands of various industries.

If you’re looking for high-quality fiberglass square tubes for your next project, visit http://incomepultrusion.com/fiberglass-square-tube/.